Argo and the environment

The Argo array provides a vital operational and research data stream that underpins important nowcast and forecast services, science, and policy assessments. The array contributes to saving lives, avoiding property damage, informing the public and government’s response to environmental variability and change, and to sustainable management of marine resources and the preservation of ocean health.

Argo uses simple profiling floats (often referred to as robotic floats, robotic profiling floats, or simply by the generic term Argo floats) that operate for 3-6 years in the ocean, returning profiles of ocean properties (temperature, salinity and, increasingly, oxygen, nutrients and bio-optical parameters) every 10 days. The floats operate throughout the global oceans, usually in remote regions where there is little ship traffic. Around 30 nations contribute to the ~3500 float array. To maintain global coverage, between 600 and 900 floats are deployed each year.

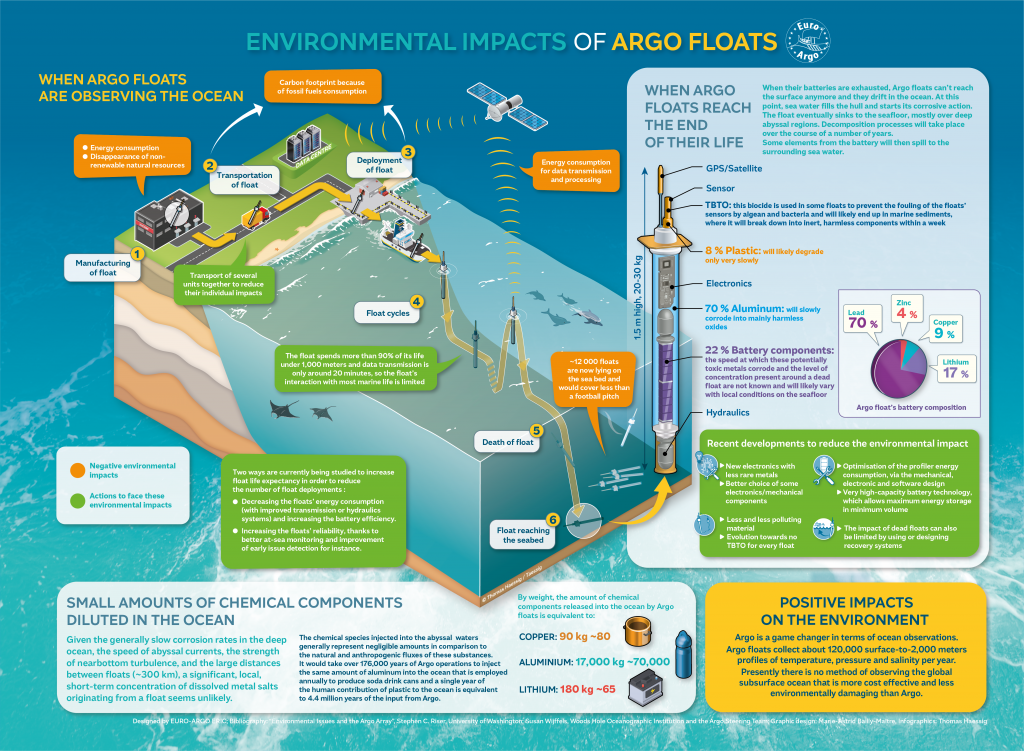

S. Riser, S. Wifjjels and the AST have written Argo’s environmental impact statement which explores this topic in detail. This webpage simply summarizes key findings from the review, so please refer to the actual statement for more information. In addition, there is now a leaflet created by EuroArgo which can be printed and folded, shown as a poster or shown on a screen. The leaflet takes the information from the impact statement and conveys it via graphics and short descriptions.

Environmental impact of the floats

As the first global-scale, subsurface ocean observing system, the Argo program has revolutionized our understanding of the ocean circulation and its relation to climate. We note that if laid side-by-side, all of the Argo floats deployed to date would cover no more than two football fields. The main environmental impact of the more than 3000 floats operational in the array is likely the release of pollutants into the ocean environment, mostly over a period of years after the floats have exhausted their batteries, begun to corrode, and sunk to the seafloor. However, the chemical species injected into the abyssal waters during this process represent generally infinitesimal amounts in comparison to the natural and anthropogenic fluxes of these substances. When comparing the amount released from 900 floats, an upper bound on the number of floats that might die per year and require replacement, Argo’s annual inputs are infinitesimally small compared to the background fluxes of these components into the ocean. For example, it would take over 176,000 years of Argo operations to inject the same amount of aluminum into the ocean that is employed annually to produce soda drink cans (200 billion per year at 15 grams/can); that a single year of the human contribution of plastic to the ocean is equivalent to 4.4 million years of the input from Argo; and that one year of the natural flux of lead into the ocean is equivalent to 83 million years of Argo operations. Moreover, the relatively large spacing between floats (~ 300 km) and the presence of often substantial currents and turbulent mixing near the seafloor suggests that it is unlikely that large, potentially harmful concentrations of these foreign substances will accrue at any given float site.

Float recovery

It has often been suggested that Argo’s environmental impact might be mitigated by recovering the floats near the end of their lives. While it might be desirable to retrieve a few floats for engineering studies or where the floats are near to ongoing vessel operations, the financial cost of the recovery of many hundreds of floats per year would be prohibitive, and the resulting ship-based carbon emissions associated with such recoveries would likely be far worse than the trace quantities of foreign substances emanating from dead floats on the seafloor.

Alternative methods of observing the subsurface ocean

Alternative (and historically very successful) methods of observing the subsurface ocean on a global scale consist of (1) ship-based XBT programs and (2) ship-based surveys employing CTD equipment and water samplers at fixed station locations. The first of these could be carried out from underway vessels, including container ships, although it is clear that true real-time, global coverage at 300 km spacing would be nearly impossible to achieve. In addition, a global XBT program equivalent to Argo would result in a massive quantity of copper wire being left in the ocean as a waste product, along with substantial amounts of zinc and plastic. In order to achieve even partial global coverage, it is likely that substantial dedicated deployment vessel time would be required, potentially resulting in large CO2 emissions. And even without these issues there is the problem that XBT data (with or without measured salinity) are unlikely to be of sufficient accuracy and precision for carrying out state-of-the-art climate research.

The second alternative, ship-based global surveys using state-of-the-art instrumentation (such as the GO-SHIP program) could observe the ocean with higher precision and accuracy than Argo, with many more quantities measured. But the costs of ship resources required to do this at the space/time resolution equivalent to Argo, along with the associated carbon emissions, would be prohibitive, with the annual financial burden of the ship time alone many times higher than the cost of several years of the Argo program.

Final thoughts

There is presently no method of observing the subsurface global ocean that is more cost effective and less environmentally damaging than Argo. Since Argo floats are mainly deployed from ships-of-opportunity, the marginal financial and environmental costs of float deployment are each relatively small. The main environmental effect of Argo comes from foreign substances released from old, dead floats on the seafloor, but the amount of these pollutants entering the ocean is extremely small compared to natural and anthropogenic fluxes. In the future there may be a cheaper and cleaner global observing system that results from improvements in Argo technology or from some new methodology that is presently unknown. In this vein, Argo will continue to work with its manufacturers to advance the technology in order to further reduce its environmental footprint, and to carry out float recoveries in cases where the added environmental footprint is not too large.