What does an Argo float do?

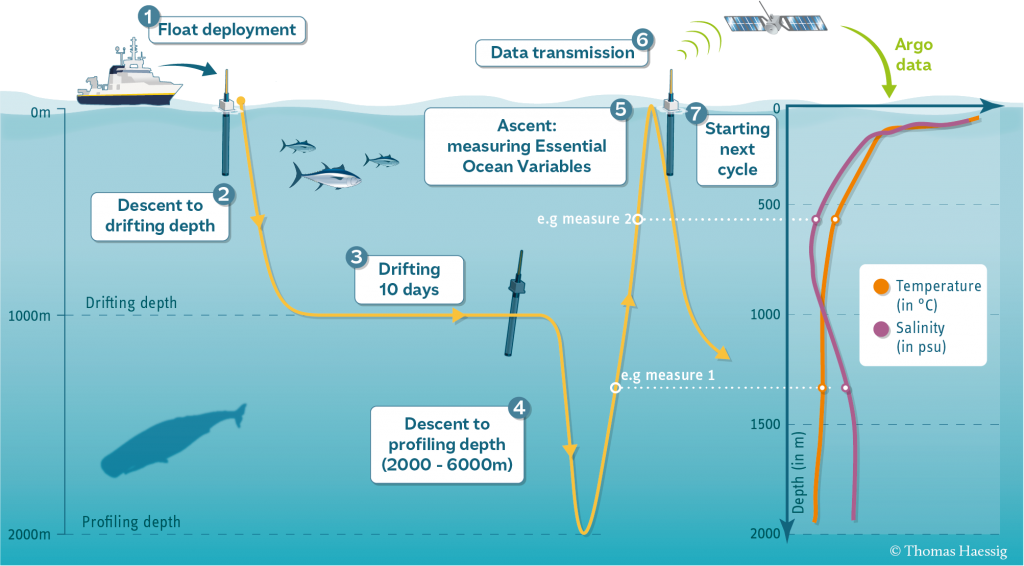

The standard Argo float mission is a 10-day cycle, with most of the float’s time spent drifting along with deep ocean currents, followed by taking a series of measurements as it moves back up (profiles) to the ocean surface. Once the float is on the surface, it gets its location, often through GPS, and then communicates with a satellite to send its data and receive any new mission instructions. For the majority of the Argo fleet, this surface interval is between 15 minutes and one hour. After that, the float sinks to a drift depth of 1000 meters for about 9 days and then the float sinks to its profile depth of 2000 meters before slowly rising to the surface while measuring conductivity, temperature and pressure. This cycle repeats until the float dies usually 4 – 5 years later.

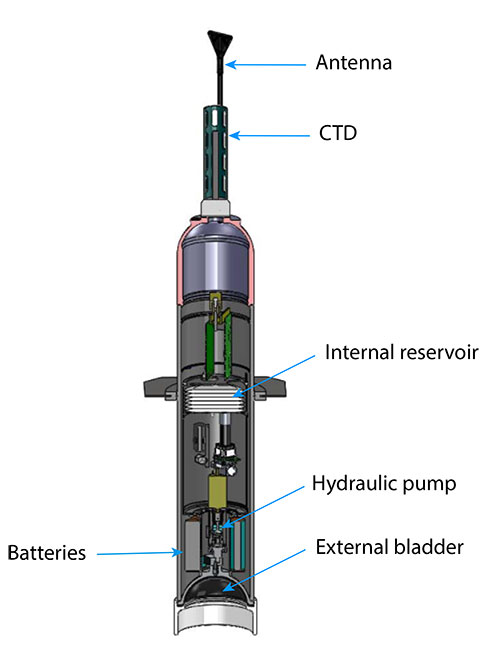

What is in an Argo float?

The different models of Argo floats made around the world have differences in both hardware and software, but mostly operate in a similar fashion.

Antenna – All Argo floats are topped with an antenna that allows them to communicate with satellites to send their data, obtain a position and find out if there is a new mission. Over half of the current Argo fleet use GPS to get their position, and Iridium satellites to transfer the data collected in the last cycle and download new mission instructions if available. Using GPS and Iridium allows floats to spend less time transmitting data at the surface, which reduces the risk of washing up on shore. This advance means that the Argo Program can put floats into marginal seas such as the Mediterranean Sea and the Gulf of Mexico. Using Iridium has also allowed for more data to be sent back, including more observations and more information about the health of the float. Instead of Iridium and GPS, some floats use Systeme Argos to both obtain a position and send back data. Due to data transmission rates and location, these floats usually need to spend 8 – 12 hours on the surface to guarantee a successful data transmission and a position accurate to ~100m.

Conductivity, Temperature, Depth sensor (CTD) – On the top of every Argo float is a CTD which measures temperature within an accuracy of 0.001 degree C , pressure (closely related to depth) within 0.1 dbar, and calculate salinity using conductivity, temperature, and pressure within 0.001 psu (practical salinity units).

Controller – Each Argo float is controlled by a small computer that contains a program to run the float.

Internal Reservoir – This area of the float stores oil when it is not inflating the external bladder.

Hydraulic pump – This mechanism moves oil between the internal reservoir and the external bladder to control the buoyancy of the float.

Batteries – Modern Argo floats use lithium batteries to power the pumps, sensors, controller, and communication system. The battery power available is the main limitation on a float’s operational lifetime.

External bladder – Roughly the size of a large grapefruit, this bladder is the mechanism by which Argo floats control their buoyancy or depth in the ocean. Inflating the bladder with oil from the internal reservoir increases the volume of the float without changing the mass, thereby lowering density and causing the float to rise. Pumping oil out of the bladder back into the reservoir will increase the float’s density, allowing it to sink to a specified depth.

To learn more about the different floats used in Argo, click here. To learn more about data transmission systems, click here. To learn more about technical innovations that have helped Argo succeed, click here.